Business

Customized Packaging Your Brand’s Impression

Customized packaging is a way to help your company stand out from competitors, and it can also attract customers. You can customize the packaging with the company’s logo, product information, or even graphics to make it look better. It is best because you have complete control of what goes on the outside while maintaining high quality. Custom boxes are becoming more popular today because they can be used to ship products to store items at home.

Custom boxes can ship their products or store things at home. When you customize the box, it is like making your company different from other companies. You can put anything on the outside of the box. For example, you could put a company logo or information about what is inside the box on there.

There are many benefits to custom packaging. It can help you increase customer experience, make a product more sellable, and help keep things from being copied. Customize your product to have these benefits.

Packaging is essential to influence a person’s decision process about what to buy. If they are already familiar with your brand, then packaging can help them feel more trusting and connected with you. It also protects the product by keeping it safe for shipment.

Protected Packaging Boxes

Packages with your logo on them can help protect your products. If they are damaged, you will lose money. But if they are protected, you won’t lose any money. Sometimes customers might not buy them because of damage.

Custom printing helps improve your company’s brand. It helps people remember what you have to offer and tell others about it.

Packaging needs to be the same as your company’s branding. Use the same colors, fonts, and images across all platforms, so people will see that you are professional. People will appreciate it when businesses take the time to personalize each interaction. Make sure that your packaging stands out too!

If you want to make your business better, invest in customized packaging. For example, you can put your company’s name or logo on the package to look better and more professional. Customers will notice the difference and appreciate it.

Product packaging printing companies are an excellent way to ensure your product will not be broken. It is also an excellent way to show what is inside. Packaging can also be used as a marketing tool. For example, a printed box with a company logo will help people recognize the brand without spending money on advertising.

You can choose different packaging for your product. You can use the standard packaging that the manufacturer provides or customize it to make it more memorable. The best part is that you have control of what goes on the outside, even while maintaining a high level of quality. For example, you can put your company logo on the packaging and information about the product and graphics to make it more attractive.

Custom-designed packaging helps you provide a better customer experience, more sales opportunities, and protection against fake products.

Let’s take a look at some of the top reasons to consider customized packaging for your brand:

-Creates a Better Customer Experience:

Customers are happier when they feel special. Customized packaging says that you care about them and give them the best possible experience with your product.

-Increases Sales Opportunities:

Customized packaging makes your product look more admirable. But it can also help you sell more of your product. People think that custom packaging is better, so they are more likely to buy things.

-Protects Against Counterfeiting:

Counterfeiting is a big problem today. Counterfeits can hurt your brand and company’s reputation, but they are also dangerous for people to use.

-Personalized:

Custom packaging is an excellent way to show customers that you care about them. People want to feel special and cared for, which they will if you use custom packaging.

-Attractive Designs:

Many companies today are choosing to use customized boxes with company logo because they look nice. They are better than regular clear plastic or cardboard boxes. A brand can still protect its products, but it will look different from other brands.

-Customer Experience:

Customers are essential to many businesses. Therefore, many businesses try to make the customer happy by ensuring that they are at the center of everything that is done.

-Variety of Uses:

Custom boxes are used for many things. For example, they can pack invitations, gifts, thank-you cards, or even print product packaging.

-Saves Money in the Long Run:

If you use customized boxes, it will cost more at first. But if you need replacements, it is better because they are higher quality and easy to reuse, which means less waste in landfills over time!

-Protect Brand Identity:

Customized boxes help protect a company’s unique identity and provide extra security during delivery. In addition, they look professional and stand out from other companies, which is suitable for any company owner.

-Sticks Out in a Crowd:

Customized boxes help protect your products during shipment. In addition, they provide safety and security for fragile items like electronics.

-Improves Customer Satisfaction:

Lastly, people will be happy if you have customized packaging printing services. They will feel better with personalized items. People will come back to you or buy your product because they are happy with the service!

If you want to make sure that people remember your brand and like it, try advertising on social media. You can save money while doing this.

When you want to ship a product, a few things need to be taken into account. One of these things is the packaging! Customized boxes with your company’s logo on them can make a product look great, and they also provide more safety and security for fragile products like electronics.

This will result in more customers over time because of this one simple thing. So it is worth it to consider doing this if you want your brand to stick out among everyone else while saving money at the same time.

When you make a product, you should put it in a package. The first thing people will see is the package. It would help if you made it eye-catching and memorable, or they will not buy your product. A custom-made package is good because people will recognize your company without reading anything on the packaging.

Business

Understanding the Web Guide Controller: An Essential Component in Modern Manufacturing

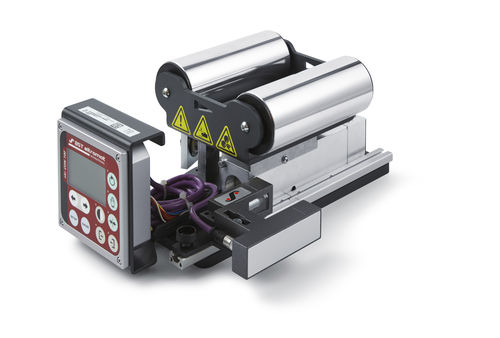

In the field of industrial automation, the web guide controller is a fundamental tool that ensures the accurate alignment of web materials throughout various manufacturing processes. This article delves into the functions, benefits, applications, and future trends associated with web guide controller, providing a comprehensive overview of their critical role in modern production environments.

What Is a Web Guide Controller?

A web guide controller is a device designed to manage and correct the alignment of web materials, such as paper, film, and foil, during manufacturing. It employs a combination of sensors and control mechanisms to maintain precise positioning and alignment, which is crucial for high-quality production.

How Web guide controller Operate

At the core of a web guide controller is its ability to detect deviations in material alignment using advanced sensors. These sensors continuously monitor the position of the web material and feed this data to the control unit. The controller then makes real-time adjustments to correct any misalignment, ensuring the material remains properly aligned throughout the production process.

Key Benefits of Using a Web Guide Controller

Incorporating a web guide controller into your production line offers several significant advantages that enhance both efficiency and quality:

Enhanced Alignment Precision

Web guide controller provide exceptional precision in aligning web materials. This precision is crucial for preventing defects and ensuring that finished products meet exact specifications. The ability to maintain accurate alignment contributes directly to product quality and consistency.

Reduction in Material Waste

By ensuring that web materials are correctly aligned, web guide controller help minimize waste caused by misalignment. This reduction in waste not only lowers production costs but also supports more sustainable manufacturing practices by maximizing material usage.

Increased Production Efficiency

The automated nature of web guide controller streamlines the production process by reducing the need for manual adjustments and interventions. This automation leads to faster production cycles and improved overall efficiency, making the manufacturing process more cost-effective.

Improved Product Quality

Consistent alignment achieved through web guide controller enhances quality control. Products produced with precise alignment are less likely to exhibit defects, ensuring they meet or exceed industry standards and customer expectations.

Applications of Web guide controller

Web guide controller are versatile devices with applications across various industries. Here’s an overview of their key uses:

Printing and Publishing

In the printing and publishing industry, web guide controller are used to align paper, film, and other substrates during the printing process. Accurate alignment is essential for ensuring that printed content, such as text and images, is correctly positioned and free from errors.

Packaging

In the packaging sector, web guide controller manage the alignment of packaging materials, including labels and films. Proper alignment is crucial for accurate label placement and effective packaging, which impacts product presentation and functionality.

Textile Production

Web guide controller are employed in textile production to align fabrics during processing stages such as coating and finishing. Accurate alignment ensures that treatments and coatings are applied evenly, resulting in high-quality textile products.

Film and Foil Manufacturing

For film and foil manufacturing, web guide controller help maintain alignment during coating and processing. Proper alignment is vital for producing films and foils that meet industry specifications and performance standards.

Emerging Trends and Innovations

As technology advances, web guide controller are expected to evolve in several key areas:

Integration with Intelligent Systems

Future web guide controller are likely to integrate with intelligent systems, such as artificial intelligence and machine learning. These advancements will enable controllers to analyze data more effectively and make precise adjustments in real time, enhancing overall performance.

Enhanced Connectivity and Data Integration

Improved connectivity will allow web guide controller to interface more seamlessly with other production equipment. This enhanced data integration will facilitate better coordination and optimization of manufacturing processes.

Greater Flexibility and Adaptability

The next generation of web guide controller will offer increased flexibility, allowing them to handle a wider range of materials and production conditions. This adaptability will make them suitable for diverse applications across different industries.

Focus on Energy Efficiency

Sustainability will become a significant focus in the development of web guide controller. Innovations may include energy-efficient designs that reduce power consumption and support environmentally friendly manufacturing practices.

Conclusion

The web guide controller is an indispensable tool in modern manufacturing, playing a critical role in maintaining precise alignment of web materials and optimizing production processes. By leveraging advanced sensors, real-time adjustments, and robust mechanical components, web guide controller contribute to enhanced precision, reduced waste, and improved product quality.

Their applications span across various industries, including printing, packaging, textile production, and film manufacturing. As technology continues to evolve, web guide controller are expected to incorporate intelligent systems, enhanced connectivity, and increased flexibility, further enhancing their capabilities and applications.

In summary, web guide controller are essential for achieving high-quality production and operational efficiency. Their ability to provide accurate alignment and automate adjustments underscores their importance in meeting industry demands and maintaining competitiveness.

Business

How Does a CO2 Laser Work? An In-Depth Look at the Mechanisms and Applications

CO2 lasers have become essential tools in various industries, ranging from manufacturing and healthcare to scientific research. Known for their high power, precision, and versatility, CO2 lasers are used for cutting, engraving, and surgical procedures. Understanding how a CO2 laser works provides insight into its applications and benefits. This article How Does a CO2 Laser Work delves into the fundamental principles of CO2 laser operation, exploring its components, processes, and technological advancements.

The Basics of CO2 Lasers

A CO2 laser, or carbon dioxide laser, utilizes carbon dioxide gas as its primary lasing medium. To comprehend its functionality, it is crucial to understand the core principles and components involved in its operation.

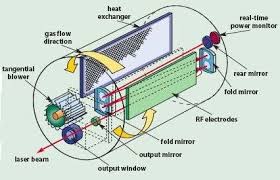

Core Components of a CO2 Laser

- Laser Medium

- The lasing medium in a CO2 laser consists of a mixture of carbon dioxide (CO2), nitrogen (N2), and helium (He) gases. The CO2 molecules are the primary source of laser light, while nitrogen and helium assist in energy transfer and heat dissipation.

- Electrical Discharge

- An electrical discharge or electrical current is used to excite the gas molecules in the laser medium. This excitation process is crucial for generating laser light.

- Laser Cavity

- The laser cavity is a chamber where the lasing action occurs. It contains two mirrors positioned at each end of the cavity: one highly reflective mirror (the end mirror) and one partially reflective mirror (the output coupler). These mirrors form an optical resonator that amplifies the light.

- Output Coupler

- The output coupler is a partially reflective mirror that allows a portion of the amplified laser light to exit the laser cavity as a coherent beam. It plays a critical role in determining the characteristics of the emitted laser beam.

How CO2 Lasers Generate Laser Light

The process of generating laser light in a CO2 laser involves several stages:

- Excitation of Gas Molecules

- When an electrical current passes through the gas mixture in the laser cavity, it excites the CO2 molecules to higher energy levels. This excitation causes the molecules to become unstable.

- Stimulated Emission

- As the excited CO2 molecules return to their ground state, they release photons (light particles) in a process known as stimulated emission. These photons have a specific wavelength, typically around 10.6 micrometers, which falls in the infrared spectrum.

- Photon Amplification

- The emitted photons travel back and forth between the two mirrors in the laser cavity. Each pass through the cavity amplifies the light due to further stimulated emission and reflection within the cavity.

- Beam Formation

- A portion of the amplified light escapes through the partially reflective output coupler. This coherent and intense beam of light is what is utilized in various applications.

The Advantages of CO2 Lasers

CO2 lasers offer several advantages that make them highly effective for specific applications:

- High Power Output

- CO2 lasers are capable of producing high power outputs, making them suitable for cutting and engraving materials with precision and efficiency. Their ability to focus a high-intensity beam allows for clean and effective processing.

- Precision and Accuracy

- The focused beam of a CO2 laser ensures precise cutting and engraving, making it ideal for applications requiring high accuracy. This precision is beneficial in fields such as manufacturing, medical procedures, and scientific research.

- Versatility in Material Processing

- CO2 lasers can process a wide range of materials, including metals, plastics, wood, glass, and textiles. This versatility makes them valuable tools in various industries, from aerospace and automotive to fashion and healthcare.

- Non-Contact Operation

- CO2 lasers operate in a non-contact manner, meaning they do not physically touch the material being processed. This characteristic reduces wear and tear on tools and minimizes the risk of contamination or damage to delicate materials.

- Low Maintenance

- CO2 lasers generally require low maintenance compared to other types of lasers. Their robust design and the absence of moving parts in the laser cavity contribute to their reliability and longevity.

Applications of CO2 Lasers

The versatility of CO2 lasers makes them suitable for a wide range of applications across different industries:

- Industrial Cutting and Engraving

- CO2 lasers are extensively used for cutting and engraving materials such as metals, plastics, wood, and glass. Their precision and high power output make them ideal for manufacturing processes, signage production, and decorative items.

- Medical Procedures

- In the medical field, CO2 lasers are employed for various surgical procedures, including skin resurfacing, tumor removal, and eye surgeries. The precision and controlled energy of CO2 lasers allow for minimally invasive procedures with reduced risk of bleeding and scarring.

- Aerospace and Automotive Industries

- CO2 lasers are used in the aerospace and automotive industries for applications such as component manufacturing, material testing, and repair. Their ability to process complex and high-strength materials is essential in these sectors.

Innovations and Future Directions

The field of CO2 laser technology continues to evolve, with ongoing research and innovations aimed at improving performance and expanding applications:

- Advanced Laser Designs

- Researchers are exploring new designs and configurations for CO2 lasers to enhance their power output, beam quality, and efficiency. Innovations such as advanced optics and improved gas mixtures are expected to drive future advancements.

- Automation and Integration

- The integration of CO2 lasers with automation and robotics is transforming manufacturing processes. Automated systems offer increased precision, speed, and flexibility, leading to improvements in production efficiency and quality.

- Emerging Applications

- New applications for CO2 lasers are being discovered, including advancements in medical treatments, environmental monitoring, and materials science. The adaptability of CO2 lasers makes them a promising technology for future developments.

Conclusion

CO2 lasers are powerful and versatile tools that play a critical role in various industries and applications. Understanding how a CO2 laser works provides valuable insights into its capabilities and benefits. By utilizing carbon dioxide gas as the lasing medium and employing sophisticated optical systems, CO2 lasers achieve high power, precision, and efficiency.

From industrial cutting and engraving to medical procedures and scientific research, CO2 lasers continue to drive innovation and progress. As technology advances and new applications emerge, CO2 lasers will remain at the forefront of optical technology, shaping the future of precision and performance in numerous fields.

Business

Revolutionizing Web Development: The Indispensable Role of NodeJS

Web development has drastically changed in the past few years with the emergence of modern frameworks and libraries that simplify the process and improve developer experience. NodeJS is one such revolutionary technology that has completely transformed the web development landscape, making it more agile, flexible, and scalable. NodeJS is a server-side JavaScript runtime environment, built on the Chrome V8 engine, which enables developers to create fast and efficient web applications. This blog post will delve into the indispensable role NodeJS plays in modern web development and why it has become the preferred choice for developers worldwide. In our present digital age, efficiency is the cornerstone of any successful website development project. NodeJS stands out in this regard. Its event-driven nature facilitates efficient handling of concurrent client requests, providing swift responses, and thus, significantly boosting the performance of web applications.

1. Speed and Scalability

One of the most significant advantages of NodeJS website development is its speed and scalability. Due to its non-blocking I/O model, Node can handle many connections at once, ensuring applications remain responsive even under heavy loads. This scalability is critical to meet the demands of today’s users, who expect real-time updates and seamless user experiences. Moreover, NodeJS’s speed makes it ideal for creating lightweight, performant APIs that can handle a massive amount of data with ease. NodeJS is not just about efficiency, it’s also about building robust, scalable web solutions. With its single-threaded model and event-driven architecture, NodeJS is primed to handle heavy traffic and deliver high-end performance, making it an excellent choice for developing large-scale applications.

2. Cross-Platform Compatibility

NodeJS website development is a cross-platform technology that can run on different operating systems, including Windows, Linux, and MacOS. This compatibility enables developers to create applications that can run in any environment, making it easier to deploy and manage applications for diverse user bases. Additionally, NodeJS’s modularity, which allows developers to use modules and packages based on their specific needs, makes it easier to handle dependencies and streamline the development process. NodeJS is also an ideal technology for developing scalable and efficient microservices architecture, as it breaks large monolithic environments into smaller-functional components. By using NodeJS to build microservices, developers can create small and manageable modules that communicate with each other through APIs. This architecture allows for better scalability, durability, and improved crash resistance. NodeJS also supports a wide range of databases, including NoSQL databases such as MongoDB, making it an ideal tool for developing database-centric applications.

3. Rich Ecosystem and Community Support

NodeJS website development has a vast collection of modules and packages available in its ecosystem, which makes it easier for developers to create applications with pre-built components. The NPM (Node Package Manager) repository is home to over 1 million modules that can be added to applications, saving developers a significant amount of time and effort. Furthermore, NodeJS has a thriving community of developers who are continually updating and improving the platform, making it easier for others to contribute to and enhance the ecosystem.

4. Microservices and DevOps

NodeJS is incredibly well-suited to the development of microservices, which are small, independent services that act together to form a complete application. Microservices architecture allows developers to create scalable, modular, and easily maintainable applications. Moreover, DevOps teams can use NodeJS to automate application deployment, testing, and monitoring, reducing the time and effort required to maintain application stability and uptime.

5. Future of Web Development

While NodeJS has been a game-changer in web development, and remains an essential technology for creating modern web applications, its benefits extend beyond in-house development teams. The rise of web development outsourcing makes NodeJS’s features even more attractive. Its speed, scalability, and cross-platform compatibility make it a perfect choice for outsourced teams working on projects with tight deadlines and ever-changing requirements. NodeJS also provides developers with an added level of flexibility that enables them to work on both the client-side and server-side of their applications. Using the same language to code across both client and server-side means that developers can create more complex applications with less complexity and optimize their applications more effectively. It also means that they can easily reuse code across different projects, enabling the efficient creation of similar but slightly different web applications.

Conclusion

NodeJS has revolutionized web development by enabling developers to create fast, efficient, and scalable applications that can run on any platform. Its rich ecosystem, cross-platform compatibility, and community support have made it popular among developers worldwide, and it continues to evolve to meet the demands of modern web development. As more businesses move towards digital transformation, NodeJS is poised to play an even more critical role in web development and is set to be an essential technology for developers for years to come. With its high scalability and performance, NodeJS has undeniably changed the game for dynamic website development. But evolution doesn’t stop here. As we look ahead, it’s clear that NodeJS will continue to play a vital role in the future of web development, pushing the boundaries of what’s possible and paving the way for the next web revolution.

-

Entertainment3 years ago

Entertainment3 years agoHow to Get Positive Feedback by Using Straight Tuck End Boxes

-

Lifestyle3 years ago

Lifestyle3 years ago13 Beautiful Decor Ideas to Add Personality to Your Hallway

-

Quote4 years ago

Quote4 years ago100+ Amazing Memorable College Life Quotes| Recall Old Days

-

Quote4 years ago

Quote4 years agoBest 100+ Heart Touching One Side Love Quotes For Him/Her

-

Quote3 years ago

Quote3 years ago50+ Famous KGF Movie Dialogues | Rocky Bhai

-

Travel3 years ago

Travel3 years agoIraqi Dinar: A Bold Move That Could Make Or Break The Currency

-

Status3 years ago

Status3 years ago201+ Love Feeling Status for Couple in English | 2022

-

Status3 years ago

Status3 years ago175+ Missing Someone Quotes For Beloved, Family, Your Friends, Your Sweetheart